Opel Insignia: Diagnostic Information and Procedures

DTC P0218

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0218

Transmission Fluid Overtemperature - Hydraulic/Mechanical Problem

Circuit/System Description

For an overview of the component/system, refer to Electronic Component Description The transmission control module monitors the transmission fluid temperature sensor to determine an overtemperature condition.

Conditions for Running the DTC

Condition 1

- DTC P0711, P0712, P0713 = Not set

- Ignition Voltage=9 to 32 V

- Vehicle Speed=Less than 180 km/h (112 MPH)

Frequency the DTC runs=Continuously - After the running conditions are met

Condition 2

- DTC P0711, P0712, P0713 = Not set

- Ignition Voltage=9 to 32 V

- Vehicle Speed=Greater than 180 km/h (112 MPH)

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

Condition 1

Transmission Fluid Temperature=Warmer than 150ºC (302ºF) - For greater than 10 s

Condition 2

Transmission Fluid Temperature=Warmer than 150ºC (302ºF) - For greater than 60 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type C DTC

Driver Information Display=Transmission Hot - Idle Engine

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type C DTC

Diagnostic Aids

Obtain additional information from the customer to determine if the vehicle has been modified, damaged or operated in any of the following conditions, which can cause the transmission to overheat:

- Driving in hot climates

- Driving in extreme off-road conditions

- Tow/haul capacity exceeded

- Towing in the incorrect gear

Reference Information

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Verify the scan tool Freeze Frame/Failure Records parameter: ECT Sensor=Colder than 125ºC (257ºF)

- If 125ºC (257ºF) or warmer

Refer to: Engine Overheating

- Go to next step: If colder than 125ºC (257ºF)

2. Verify the condition does not exist: Incorrect fluid level or condition - Transmission - Refer to Transmission Fluid Level and Condition Check

- If a condition exists

Repair or replace as necessary.

- Go to next step: If no condition exists

3. Verify the condition does not exist: Overheating - Transmission - Refer to: Transmission Overheats

- If a condition exists

Repair or replace as necessary.

- Go to next step: If no condition exists

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If any DTC is set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no DTC is set

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Transmission Fluid Drain and Fill

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0601, P0602, P0603, or P0604

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0601

Control Module Read Only Memory Performance

DTC P0602

Control Module Not Programmed

DTC P0603

Control Module Long Term Memory Reset

DTC P0604

Control Module Random Access Memory Performance

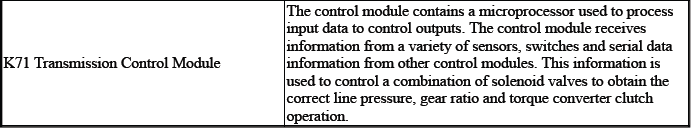

Circuit/System Description

For an overview of the component/system, refer to Electronic Component Description This diagnostic applies to microprocessor integrity conditions within the control module. This diagnostic also checks if the control module is not programmed, or is programmed incorrectly.

Conditions for Running the DTC

Ignition Voltage=On

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0601

ROM Malfunction

P0602

Programming Malfunction

P0603

EEPROM Performance/Malfunction

P0604

RAM Malfunction

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

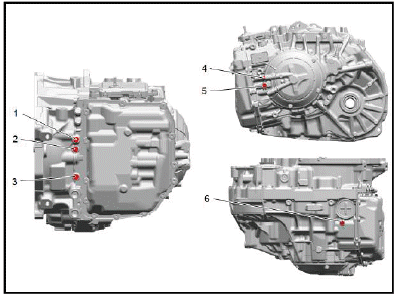

Component View: Reference

Refer to Disassembled Views

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify DTC P0601, P0602, P0603, P0604 is not set.

- If the DTC is set

- Perform all necessary programming and setup procedures for the control module:K71 Transmission Control Module

- Verify the DTC does not set.

- If the DTC sets - Replace the component:K71 Transmission Control Module

- Go to next step: If the DTC is not set

- All OK.

- Go to next step: If the DTC is not set

3. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0606, P177F, P2637, or P2638

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0606

Control Module Processor Performance

DTC P177F

Detected Gear Incorrect

DTC P2637

Torque Increase Calculation Malfunction

DTC P2638

Breaking Torque Calculation Malfunction

Circuit/System Description

For an overview of the component/system, refer to Electronic Component Description

Conditions for Running the DTC

P0606Condition 1

Engine=Running - For greater than 10 min

Frequency the DTC runs=Continuously - After the running conditions are met

Condition 2

K71 Transmission Control Module=During control module power down

Frequency the DTC runs=Continuously - After the running conditions are met

P177F

DTC P0606 = Not set

Frequency the DTC runs=Continuously - After the running conditions are met

P2637

Engine=Running

Frequency the DTC runs=Continuously - After the running conditions are met

P2638

Ignition=On

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0606Condition 1

K71 Transmission Control Module=Internal Malfunction

Condition 2

Pressure Control Solenoid Valve=Commanded state does not match the actual state

P177F

Commanded gear=Incorrect - Engine Overspeed

P2637

Requested Torque Signal=Greater than a predefined threshold - For greater than 1 s

P2638

Automatic Braking Torque=Greater than a predefined threshold

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below

DTC P2637=Type B

One or more of the following may occur:

- K71 Transmission Control Module=Reset

- Transmission gear allowed=3rd Gear

- TCM Requested Torque=0 Nm (0 lb ft)

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A - Exceptions listed below

DTC P2637=Type B

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify DTC P0606, P177F, P2637, P2638 is not set.

- If the DTC is set

- Perform all necessary programming and setup procedures for the control module:K71 Transmission Control Module

- Verify the DTC does not set.

- If the DTC sets - Replace the component:K71 Transmission Control Module

- Go to next step: If the DTC is not set

- All OK.

- Go to next step: If the DTC is not set

3. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification.

For control module replacement, programming, and setup: Refer to Control Module: References.

DTC P0657

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Diagnostic Procedure Instructions

DTC Descriptor

DTC P0657

Actuator High Control Circuit Group 1

Circuit/System Description

For an overview of the component/system, refer to Electronic Component Description This diagnostic applies to microprocessor integrity conditions within the control module. This diagnostic also checks if the control module is not programmed, or is programmed incorrectly.

Conditions for Running the DTC

K71 Transmission Control Module=Communication Enabled

Conditions for Setting the DTC

K71 Transmission Control Module=Internal Malfunction

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify DTC P0657 is not set.

- If the DTC is set

- Perform all necessary programming and setup procedures for the control module:K71 Transmission Control Module

- Verify the DTC does not set.

- If the DTC sets - Replace the component:K71 Transmission Control Module

- Go to next step: If the DTC is not set

- All OK.

- Go to next step: If the DTC is not set

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0705, P0707, P0708, or P0851

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

NOTE: This procedure may also diagnose malfunctions that are not detected by a DTC.

DTC P0705

Transmission Range Switch Circuit

DTC P0707

Transmission Range Switch Circuit Low Voltage

DTC P0708

Transmission Range Switch Circuit High Voltage

DTC P0851

Park/Neutral Position Switch Circuit Low Voltage

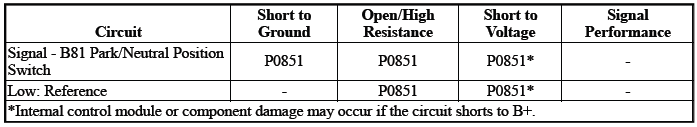

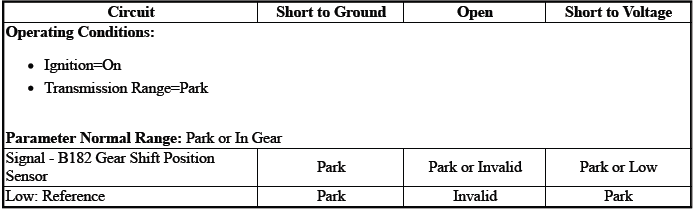

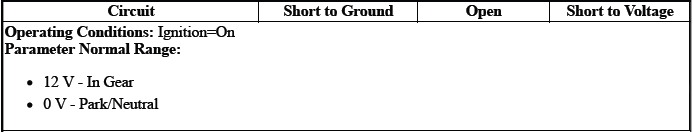

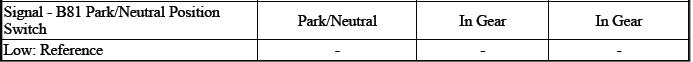

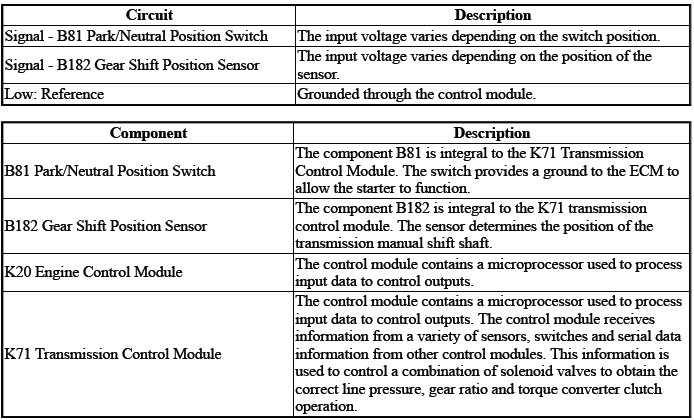

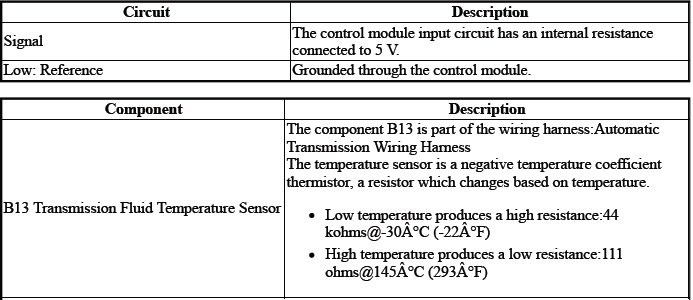

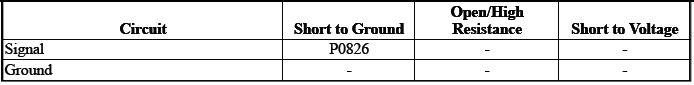

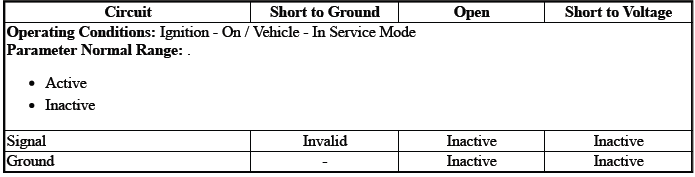

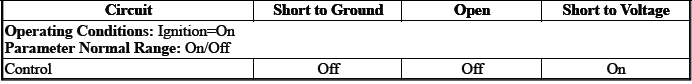

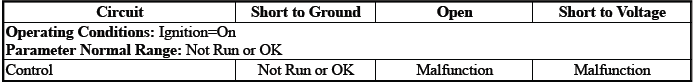

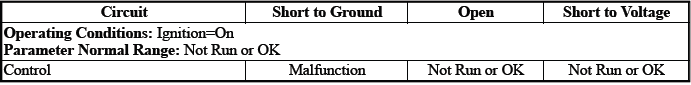

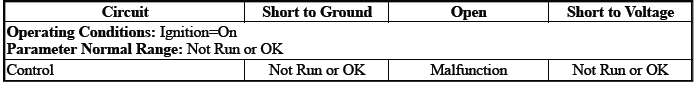

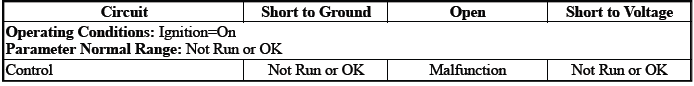

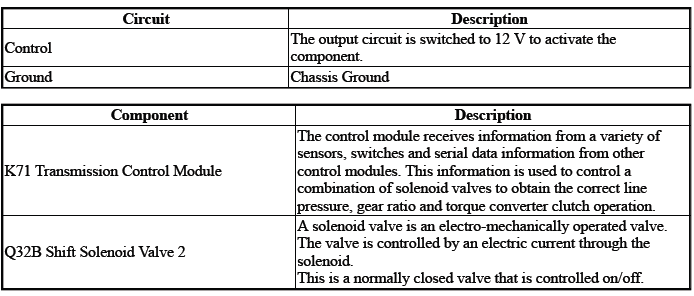

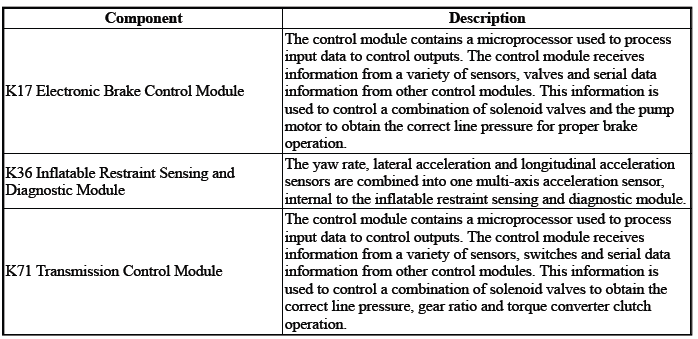

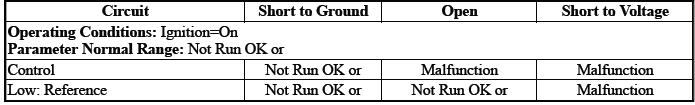

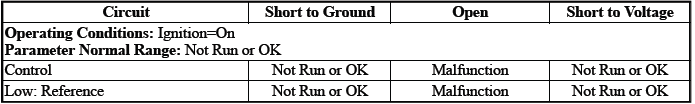

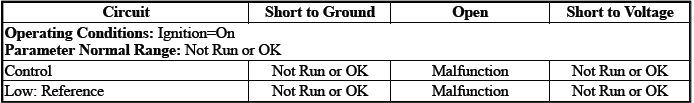

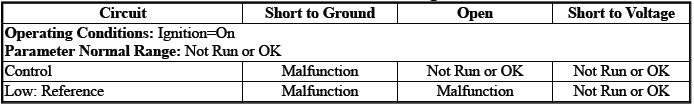

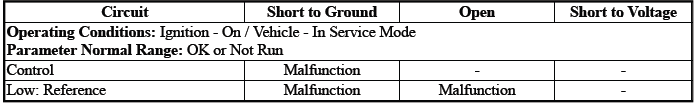

Diagnostic Fault Information

Typical Scan Tool Data

Transmission Range Switch

Park/Neutral Position Switch

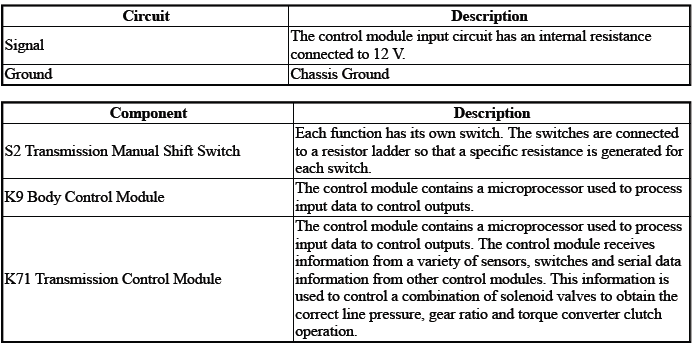

Circuit/System Description

P0705, P0707, P0708

The sensor is an input to the control module K71. The control module K71 uses the information from the sensor signal B182 to determine what transmission gear range the vehicle operator selected.

The control module uses this data, along with other data, to adjust or control the following:

- Q23 Line Pressure Control Solenoid Valve

- Q27A Pressure Control Solenoid Valve 1

- Q27B Pressure Control Solenoid Valve 2

- Q27C Pressure Control Solenoid Valve 3

- Q27D Pressure Control Solenoid Valve 4

- Q27E Pressure Control Solenoid Valve 5

- Q27F Pressure Control Solenoid Valve 6

- Q27G Pressure Control Solenoid Valve 7{ If equipped }

- Q32A Shift Solenoid Valve 1

- Q32B Shift Solenoid Valve 2

- Q39A Torque Converter Clutch Pressure Control Solenoid Valve

P0851

The sensor is an input to the control module K20.

The control module uses this data, along with other data, to adjust or control the following: KR27 Starter Relay

Conditions for Running the DTC

P0705, P0707, P0708

- DTC P0851 = Not set

- K71 Transmission Control Module=Communication Enabled

- Ignition Voltage=10 to 16 V

- Service Mode=Disabled

Frequency the DTC runs=Continuously - After the running conditions are met

P0851

- Engine Torque= Greater than 75 Nm (55 lb ft)

- Ignition Voltage=10 to 16 V

- Selector Lever Position= P or N

- Throttle Position Sensor=Greater than 8%

- Vehicle Speed=Greater than 10 km/h (6 MPH)

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0705

Position 1 & Position 2=Not between 4.71 and 5.29 V - For greater than 1 s & For 2 consecutive events.

P0707

Position 1orPosition 2=Less than 0.127 V - For greater than 1 s & For 2 consecutive events.

P0708

Position 1orPosition 2=Greater than 4.87 V - For greater than 1 s & For 2 consecutive events.

P0851

Engine Control Module - Vehicle Speed Detected=Greater than 10 km/h (6 MPH) & Park/Neutral Position Switch=Park/Neutral - For greater than 2 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below - Additional actions taken:

- Transmission Learn=Disabled

- Transmission gear allowed=3rd Gear - After a stop

- Engine Cranking=Disabled

DTC P0851=Type C DTC

Engine Cranking=Disabled

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below

DTC P0851=Type C DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

- Refer to Electronic Component Description

- Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify there are no DTCs set related to the following system/component:K173 Transmission Range Control Module - If equipped

- If any DTC is set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no DTC is set

3. Transmission - Park

4. Verify the scan tool parameter: Park/Neutral Position Switch@K20 Engine Control Module=Park

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

5. Transmission - Neutral - Brake Applied

6. Verify the scan tool parameter:Park/Neutral Position Switch@K20 Engine Control Module=Neutral

- If not the specified state

Refer to Circuit/System Testing

7. Transmission - Park

8. Verify the scan tool parameter: Transmission Range Switch@K71 Transmission Control Module=Park

- If not the specified state

Replace the component: K71 Transmission Control Module

- Go to next step: If the specified state

9. Operate the component: S3 Transmission Shift Lever

Verify the scan tool parameter: Transmission Range Switch=Matches the selector lever position

- If not the specified state

Replace the component:K71 Transmission Control Module

- Go to next step: If the specified state

10. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

11. All OK.

Circuit/System Testing

NOTE: Circuit/System Verification must be performed before proceeding with Circuit/System Testing.

1. Ignition/Vehicle & All vehicle systems - Off.

2. Disconnect the electrical connector:X1 @K71 Transmission Control Module.

3. Ignition - On / Vehicle - In Service Mode.

4. Test for greater than 9 V between the test points: Signal circuit terminal 5 & Ground.

- If less than 9 V

- Disconnect the electrical connector:X1@K20 Engine Control Module

- Test for infinite resistance between the test points: Signal circuit

terminal 5@Component harness &

Ground

- If less than infinite resistance

Repair the short to ground on the circuit.

- Go to next step: If infinite resistance

- If less than infinite resistance

- Test for less than 2 ohms between the test points:

- If 2 ohms or greater

Repair the open/high resistance in the circuit.

- If less than 2 ohms

Replace the component:K20 Engine Control Module

- If 2 ohms or greater

- Go to next step: If greater than 9 V

5. Ignition/Vehicle - Off.

6. Test for less than 1 V between the test points: Signal circuit terminal 5@Component harness & Ground.

- If 1 V or greater

Repair the short to voltage on the circuit.

- Go to next step: If less than 1 V

7. Test or replace the component: Park/Neutral Position Switch

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Transmission Control Module Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0711-P0713

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0711

Transmission Fluid Temperature Sensor Performance

DTC P0712

Transmission Fluid Temperature Sensor Circuit Low Voltage

DTC P0713

Transmission Fluid Temperature Sensor Circuit High Voltage

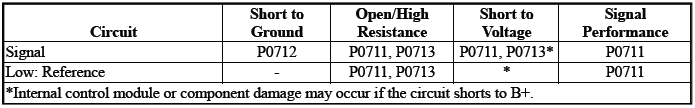

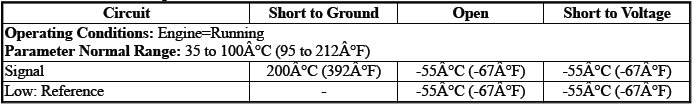

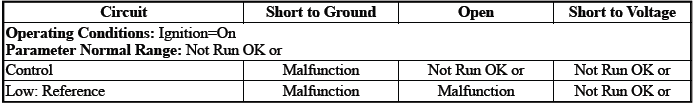

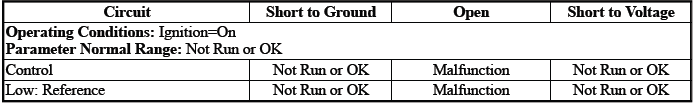

Diagnostic Fault Information

Typical Scan Tool Data

Transmission Fluid Temperature

Circuit/System Description

For an overview of the component/system, refer to Transmission General Description

The sensor is an input to the control module K71. The input signal is used to determine the temperature of the fluid: Transmission

The control module uses this data, along with other data, to adjust or control the following:

- Driver Alert Indicator - Transmission Hot - Idle Engine

- Line Pressure

- Torque Converter Clutch

- Transmission Adaptive Values Learn

- Transmission Hot Mode

- Transmission Shifting

Conditions for Running the DTC

P0711

- DTC P0705, P0707, P0708, P0712, P0713 = Not set

- Engine Speed= Greater than 400 RPM

- Ignition Voltage=9 to 32 V

- Fail-Safe Mode=Inactive

- K71 Transmission Control Module= Communication Enabled

- Service Mode=Disabled

Frequency the DTC runs=Continuously - After the running conditions are met - For greater than 2 s

P0712

Ignition Voltage=9 to 32 V

Frequency the DTC runs=Continuously - After the running conditions are met - For greater than 2 s

P0713

- DTC P0705, P0707, P0708 = Not set

- Engine Speed= Greater than 400 RPM

- Ignition Voltage=9 to 32 V

- Transmission Range= Drive

Frequency the DTC runs=Continuously - After the running conditions are met - For greater than 2 s

Conditions for Setting the DTC

P0711Condition 1

Transmission Fluid Temperature & Engine Coolant Temperature=Not within 43ºC (77ºF) of each other

Condition 2

Transmission Fluid Temperature=The temperature does not change within 10 min & The vehicle speed has reached 40 km/h (29 MPH) at least once during this drive cycle.

Condition 3

Transmission Fluid Temperature=The temperature does not change within a predetermined time.

P0712

Transmission Fluid Temperature=Warmer than 200ºC (392ºF) - For greater than 60 s

P0713

Transmission Fluid Temperature=Colder than -55ºC (-67ºF) - For greater than 12 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type B DTC

- Autostart/Autostop=Disabled - If equipped

- Torque Converter Clutch=Disabled

- Transmission Adaptive Values Learn=Disabled

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type B DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Verify the condition does not exist: Incorrect fluid level or condition - Transmission - Refer to Transmission Fluid Level and Condition Check

- If a condition exists

Refer to Fluid Leak Diagnosis

- Go to next step: If no condition exists

2. Verify the scan tool parameter: Transmission Fluid Temperature=-39 to 199ºC (-39 to 390ºF)

- If not between -39 and 199ºC (-39 and 390ºF)

Refer to Circuit/System Testing

- Go to next step: If between -39 and 199ºC (-39 and 390ºF)

3. Operate the cold vehicle above 64 km/h (40 MPH) for 10 min.

Verify the scan tool parameter: Transmission Fluid Temperature=Temperature increases greater than 2ºC (4ºF)

- If the temperature does not increase 2ºC (4ºF) or greater

Refer to Circuit/System Testing

- Go to next step: If the temperature increases greater than 2ºC (4ºF)

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

5. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

2. Remove the component: K71 Transmission Control Module.

3. Test for infinite resistance between the test points: Low: Reference circuit terminal 19 & Transmission Case.

- If less than infinite resistance

Replace the component: Automatic Transmission Wiring Harness

- Go to next step: If infinite resistance

4. Test for infinite resistance between the test points: Signal circuit terminal 10 & Transmission Case

- If less than infinite resistance

Replace the component: Automatic Transmission Wiring Harness

- Go to next step: If infinite resistance

5. Test the resistance between the test points: Low: Reference circuit terminal 19 & Signal circuit terminal 10

Verify the value is within the range listed in the table: Refer to Temperature Versus Resistance (B13 Transmission Fluid Temperature Sensor) Refer to Temperature Versus Resistance (Q27 Pressure Control Solenoid Valve) Refer to Temperature Versus Resistance (Q32 Shift Solenoid Valve 1)

- If in the specified range

Replace the component: K71 Transmission Control Module

- Go to next step: If not in the specified range

6. Test or replace the component: Automatic Transmission Wiring Harness

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Wiring Harness Wire Replacement - Automatic Transmission Wiring Harness

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0717, P07BF, or P07C0

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0717

Input Speed Sensor Circuit No Signal

DTC P07BF

Input Speed Sensor Circuit Low Voltage

DTC P07C0

Input Speed Sensor Circuit High Voltage

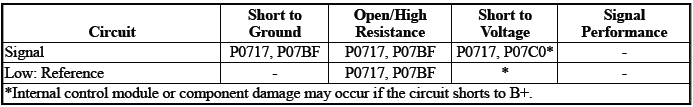

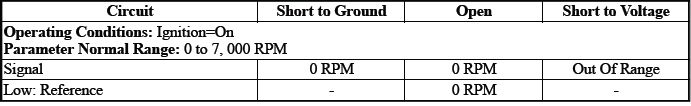

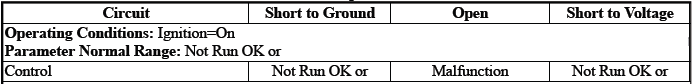

Diagnostic Fault Information

Typical Scan Tool Data

Transmission ISS

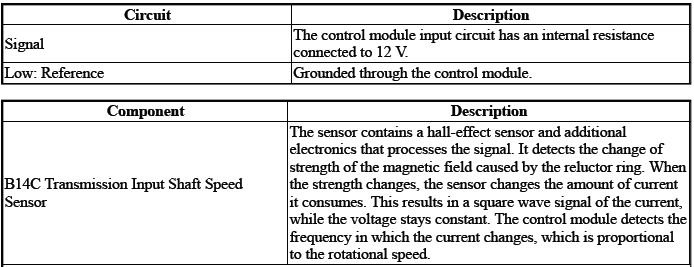

Circuit/System Description

The sensor is an input to the control module K71. The input signal is used to determine the rotational speed of the component: Input Shaft

The control module uses this data, along with other data, to adjust or control the following:

- Torque Converter Clutch

- Transmission Shifting

Conditions for Running the DTC

P07BF, P07C0

- Ignition Voltage=10.2 to 15.5 V

- K71 Transmission Control Module= Communication Enabled

Frequency the DTC runs=Continuously - After the running conditions are met - For 2 s

Conditions for Setting the DTC

P0717

Transmission ISS=0 RPM & Transmission OSS=Greater than 0 RPM

P07BF

Transmission ISS=Invalid Signal Received - Short to Ground

P07C0

Transmission ISS=Invalid Signal Received - Short to Voltage

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

- Autostart/Autostop=Disabled - If equipped

- Fail-Safe Mode=Active

- Learning=Disabled

- Torque Converter Clutch=Disabled

- Transmission OSS=Calculated

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Engine - Running.

2. Transmission - Park.

3. Verify the scan tool parameter: Transmission ISS=Engine Speed.

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

4. Transmission - Reverse.

5. Verify the scan tool parameter: Transmission ISS= 0.

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

6. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

7. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off

2. Remove the component:K71 Transmission Control Module

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

3. Test for 4500000 to 5000000 ohms between the test points:Signal circuit terminal 18 & Low: Reference circuit terminal 17

- If not between 4500000 and 5000000 ohms

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:B14C Transmission Input Shaft Speed Sensor

- Test for less than 2 ohms between the test points:

- Control circuit terminal 2@Component harness & Signal circuit terminal 18@Control module harness

- Low: Reference circuit terminal 1@Component harness & Low: Reference circuit terminal 17@Control module harness

- If 2 ohms or greater - Replace the component:Automatic Transmission Wiring Harness

- If less than 2 ohms - Replace the component:B14C Transmission Input Shaft Speed Sensor

- Go to next step: If between 4500000 and 5000000 ohms

4. Test for infinite resistance between the test points:

- Signal circuit terminal 18 & Transmission Case

- Low: Reference circuit terminal 17 & Transmission Case

- If less than infinite resistance

- Remove the component: Control Valve Body Cover

- Disconnect the electrical connector:B14C Transmission Input Shaft Speed Sensor

- Test for infinite resistance between the test points:

- Signal circuit terminal 2@Component harness & Transmission Case

- Low: Reference circuit terminal 1@Component harness & Transmission Case

- If less than infinite resistance - Replace the component: Automatic

Transmission Wiring Harness.

If less than infinite resistance - Replace the component:B14C Transmission Input Shaft Speed Sensor.

- Go to next step: If infinite resistance

5. Replace the component:K71 Transmission Control Module

Component Testing

1. Ignition/Vehicle - Off.

2. Disconnect the electrical connector:B14C Transmission Input Shaft Speed Sensor.

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 4500000 to 5000000 ohms between the test points: Control terminal 2 & Low: Reference terminal 1.

- If not between 4500000 and 5000000 ohms

Replace the component:B14C Transmission Input Shaft Speed Sensor

- Go to next step: If between 4500000 and 5000000 ohms

4. Test for infinite resistance between the test points:Each terminal of the component & The component's housing.

- If less than infinite resistance

Replace the component:B14C Transmission Input Shaft Speed Sensor

- Go to next step: If infinite resistance

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Input Speed Sensor Replacement

- Refer to Wiring Harness Wire Replacement - Automatic Transmission Wiring Harness

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0722, P077C, or P077D

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis:Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0722

Output Speed Sensor Circuit No Signal

DTC P077C

Output Speed Sensor Circuit Low Voltage

DTC P077D

Output Speed Sensor Circuit High Voltage

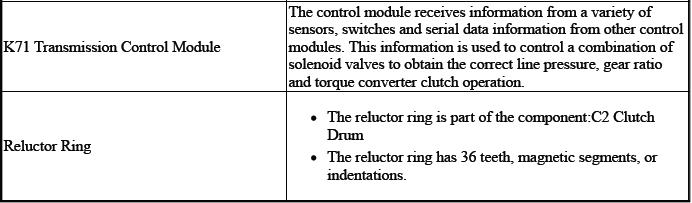

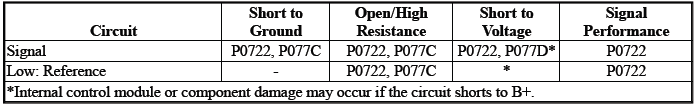

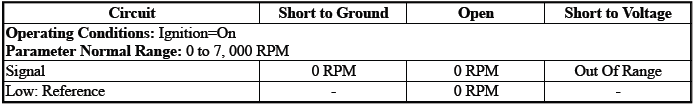

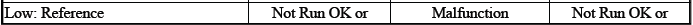

Diagnostic Fault Information

Typical Scan Tool Data

Transmission OSS

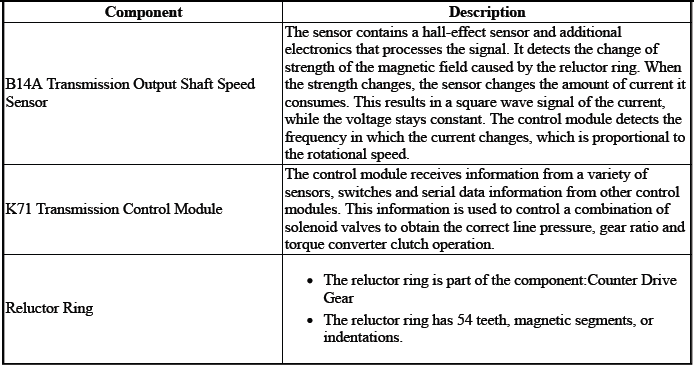

Circuit/System Description

The sensor is an input to the control module K71. The input signal is used to determine the rotational speed of the component:Output Shaft The control module uses this data, along with other data, to adjust or control the following:

- Torque Converter Clutch

- Transmission Shifting

Conditions for Running the DTC

P0722

- DTC P077C, P077D, P07BF, P07C0, P0973, P0974, P0748, P0778, P0798,

P0962, P0963, P0967, P0970.

P0971, P2716, P2720, P2721, P2725, P2729, P2730, P2734, P2738, P2739 = Not set

- Engine Speed= Greater than 400 RPM

- Fail-Safe Mode=Inactive

- Ignition Voltage=10.2 to 15.5 V

- K71 Transmission Control Module= Communication Enabled

- Transmission Range=Drive

Frequency the DTC runs=Continuously - After the running conditions are met - For 2 s

P077C, P077D

- Engine Speed= Greater than 400 RPM

- Ignition Voltage=10.2 to 15.5 V

- K71 Transmission Control Module= Communication Enabled

Frequency the DTC runs=Continuously - After the running conditions are met - For 2 s

Conditions for Setting the DTC

P0722

Transmission OSS=0 RPM & Transmission ISS=Greater than 0 RPM

P077C

Transmission OSS=Invalid Signal Received - Short to Ground

P077D

Transmission OSS=Invalid Signal Received - Short to Voltage

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

- Autostart/Autostop=Disabled - If equipped

- Fail-Safe Mode=Active

- { P077C, P077D }Transmission gear allowed=4th Gear - After a stop

- { P0722 }Transmission gear allowed=6th gear

- Transmission ISS=Calculated

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Engine - Running.

2. Transmission - Park.

CAUTION: Support the lower control arms in the normal horizontal position in order to avoid damage to the drive axles. Do not operate the vehicle in gear with the wheels hanging down at full travel.

3. Raise and support the vehicle.

4. Transmission - Drive.

5. Verify the scan tool parameter:Transmission OSS=The value should change smoothly and gradually as the vehicle speed is increased and decreased.

- If the value does not change smoothly and gradually

Refer to Circuit/System Testing

- Go to next step: If the value does not change smoothly and gradually

6. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

7. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off.

2. Remove the component:K71 Transmission Control Module.

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

3. Test for 4500000 to 5000000 ohms between the test points:Signal circuit terminal 11 & Low: Reference circuit terminal 20

- If not between 4500000 and 5000000 ohms

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:B14C Transmission Input Shaft Speed Sensor

- Test for less than 2 ohms between the test points:

- Control circuit terminal 2@Component harness & Signal circuit terminal 11@Control module harness

- Low: Reference circuit terminal 1@Component harness & Low: Reference circuit terminal 20@Control module harness

- If 2 ohms or greater - Replace the component:Automatic Transmission Wiring Harness

- If less than 2 ohms - Replace the component:B14C Transmission Input Shaft Speed Sensor

- Go to next step: If between 4500000 and 5000000 ohms

4. Test for infinite resistance between the test points:

- Signal circuit terminal 11 & Transmission Case

- Low: Reference circuit terminal 20 & Transmission Case

- If less than infinite resistance

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:B14C Transmission Input Shaft Speed Sensor

- Test for infinite resistance between the test points:

- Signal circuit terminal 2@Component harness & Transmission Case

- Low: Reference circuit terminal 1@Component harness & Transmission Case

- If less than infinite resistance - Replace the component:Automatic Transmission Wiring Harness

- If less than infinite resistance - Replace the component:B14A Transmission Output Shaft Speed Sensor

- Go to next step: If infinite resistance

- Go to next step: If infinite resistance

5. Replace the component:K71 Transmission Control Module

Component Testing

1. Ignition/Vehicle - Off.

2. Disconnect the electrical connector:B14A Transmission Output Shaft Speed Sensor.

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 4500000 to 5000000 ohms between the test points:Control terminal 2 & Low: Reference terminal 1.

- If not between 4500000 and 5000000 ohms

Replace the component:B14A Transmission Output Shaft Speed Sensor

- Go to next step: If between 4500000 and 5000000 ohms

4. Test for infinite resistance between the test points:Each terminal of the component & The component's housing.

- If less than infinite resistance

Replace the component:B14A Transmission Output Shaft Speed Sensor

- Go to next step: If infinite resistance

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Counter Drive Gear Removal - B14A Transmission Output Shaft Speed Sensor

- Refer to Counter Drive Gear Installation - B14A Transmission Output Shaft Speed Sensor

- Refer to Wiring Harness Wire Replacement - Automatic Transmission Wiring Harness

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0729-P0735, P076F, or P07D9

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis:Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0729

6th Gear Ratio Incorrect

DTC P0730

Gear Ratio Incorrect

DTC P0731

1st Gear Ratio Incorrect

DTC P0732

2nd Gear Ratio Incorrect

DTC P0733

3rd Gear Ratio Incorrect

DTC P0734

4th Gear Ratio Incorrect

DTC P0735

5th Gear Ratio Incorrect

DTC P076F

7th Gear Ratio Incorrect

DTC P07D9

8th Gear Ratio Incorrect

Circuit/System Description

The control module calculates gear ratio based on information from various transmission sensors and information obtained from other control modules. If the commanded gear ratio does not match the calculated gear ratio, a DTC sets.

Conditions for Running the DTC

- DTC P0711, P0712, P0713, P0742, P0717, P07BF, P07C0, P0722, P077C, P077D = Not set

- B14A Transmission Output Shaft Speed Sensor=Greater than 59 RPM

- K71 Transmission Control Module= Communication Enabled

- Ignition Voltage=9 to 32 V

- Transmission Fluid Temperature=Warmer than -20ºC (-4ºF)

- Transmission Range= Drive

- {P0729Condition 1}Transmission Gear=6th gear

- {P0729Condition 2}Transmission Gear=6th gear & Engine Torque=Greater than 59 Nm (44 lb ft)

- {P0730Condition 1}Transmission Gear=1st Gear & Engine Torque=Less than 0 Nm (0 lb ft)

- {P0730Condition 2}Transmission Gear=1st Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P0730Condition 3}Transmission Gear=1st Gear & Engine Torque=Greater than 59 Nm (44 lb ft) & B14C

- Transmission Input Shaft Speed Sensor=Less than 6001 RPM {P0731}Transmission Gear=1st Gear & Engine Torque=Greater than 59 Nm (44 lb ft) & B14C Transmission

- Input Shaft Speed Sensor =Less than 6001 RPM

- {P0732Condition 1}Transmission Gear=2nd Gear

- {P0732Condition 2}Transmission Gear=2nd Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P0733Condition 1}Transmission Gear=3rd Gear

- {P0733Condition 2}Transmission Gear=3rd Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P0734Condition 1}Transmission Gear=4th Gear

- {P0734Condition 2}Transmission Gear=4th Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P0735Condition 1}Transmission Gear=5th Gear

- {P0735Condition 2}Transmission Gear=5th Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P076FCondition 1}Transmission Gear=7th Gear {P076FCondition 2}Transmission Gear=7th Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

- {P07D9Condition 1}Transmission Gear=8th Gear

- {P07D9Condition 2}Transmission Gear=8th Gear & Engine Torque=Less than -20 Nm (-15 lb ft) or Greater than 29 Nm (21 lb ft)

Frequency the DTC runs=Continuously - After the running conditions are met - For 2 s

Conditions for Setting the DTC

P0729, P0730, P0732, P0733, P0734, P0735, P076F, P07D9 - Condition 1

The following parameters are not within 20% of each other:Gear Ratio & Gear Command - For 1 s - Malfunction occurred 5 times.

P0729Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 4, 5, 7, 8 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0730Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 3, 4 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0730Condition 3

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 5 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0731

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 4, 5 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0732Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 3, 4, 5, 8 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0733Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 4, 5, 7 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0734Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 3, 5, 6 ratio - For greater than 1 s - Malfunction occurred 5 times.

P0735Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 3, 4, 6, 7, 8 ratio - For greater than 1 s - Malfunction occurred 5 times.

P076FCondition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 3, 5, 6, 8 ratio - For greater than 1 s - Malfunction occurred 5 times.

P07D9Condition 2

Gear Ratio=Incorrect gear ratio - Within 4% of gear 2, 5, 6, 7 ratio - For greater than 1 s - Malfunction occurred 5 times.

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC - Exceptions listed below - Additional actions taken:

DTC P0730=Type C DTC

- Autostart/Autostop=Disabled - If equipped

- Fail-Safe Mode=Enabled

- Learning=Disabled

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

DTC P0730=Type C DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics

Connector End View: Reference

Refer to Component Connector End View Index

Component View: Reference

Refer to Disassembled Views

Description and Operation

Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions

Scan Tool: Reference

Refer to Control Module: References

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify there are no DTCs set related to the following system/component:

- Q27A Pressure Control Solenoid Valve 1

- Q27B Pressure Control Solenoid Valve 2

- Q27C Pressure Control Solenoid Valve 3

- Q27D Pressure Control Solenoid Valve 4

- Q27E Pressure Control Solenoid Valve 5

- Q27F Pressure Control Solenoid Valve 6

- Q32A Shift Solenoid Valve 1

- Q32B Shift Solenoid Valve 2

- If other DTCs are set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no other DTCs are set

3. Verify the condition does not exist:Incorrect fluid level or condition - Transmission - Refer to Transmission Fluid Level and Condition Check

- If a condition exists

Repair or replace as necessary.

- Go to next step: If no condition exists

4. Verify the condition does not exist:Incorrect pressure - Transmission - Refer to Line Pressure Check

- If a condition exists

Replace the component:T12 Automatic Transmission Assembly

- Go to next step: If no condition exists

5. Clear the DTCs.

6. Perform the configuration/reset function: Refer to Learned Values Reset

7. Road test the vehicle. - Refer to Road Test.

8. Verify DTC P0729, P0730, P0731, P0732, P0733, P0734, P0735, P076F, P07D9 is not set.

- {Test failed 1 time (s) }If any of the DTCs are set

- Replace the component: K71 Transmission Control Module

- Refer to:Step 5

- {Test failed 2 time (s) }If any of the DTCs are set

- Replace the component: Control Valve Body

- Refer to:Step 5

- {Test failed 3 time (s) }If any of the DTCs are set

- Replace the component: T12 Automatic Transmission Assembly

- Refer to:Step 5

- Go to next step: If none of the DTCs are set

9. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to:Step 1

- Go to next step: If the DTC is not set

10. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Transmission Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0741 or P0742

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis:Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0741

Torque Converter Clutch (TCC) Pressure Control Solenoid Valve Stuck Off

DTC P0742

Torque Converter Clutch (TCC) System Stuck On

Circuit/System Description

The following inputs are used to determine TCC slip speed:

- Crankshaft Position Sensor

- Transmission ISS

When the amount of TCC slip is greater than desired, DTC P0741 sets.When the amount of TCC slip is less than desired, DTC P0742 sets.

Conditions for Running the DTC

- DTC P0711, P0712, P0713 P0717, P07BF, P07C0, P0722, P077C, P077D, P2761, P2763, P2764 = Not set

- { P0742 }Engine Speed=1000 to 3000 RPM & Engine Torque=Greater than 60 Nm (44 lb ft)

- { P0741 }Engine Speed=Less than 4001 RPM & Engine Torque=Greater than 0 Nm (0 lb ft)

- Ignition=9 to 32 V

- Transmission Range=Drive

- Transmission Fluid Temperature=Greater than 19ºC (66ºF)

Frequency the DTC runs=Continuously - After the running conditions are met - For 2 s

Conditions for Setting the DTC

P0741

Torque Converter Clutch=Applied & TCC Slip Speed=Greater than 100 RPM - For greater than 18 s

P0742

Torque Converter Clutch=Released & TCC Slip Speed=Less than 30 RPM - For greater than 24 s

Actions Taken When the DTC Sets

DTC P0741=Type B DTC

DTC P0742=Type C DTC

- { P0742 }Autostart/Autostop=Disabled - If equipped

- Learning=Disabled

- Torque Converter Clutch=Disabled

Conditions for Clearing the DTC

DTC P0741=Type B DTC

DTC P0742=Type C DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics.

Connector End View: Reference

Refer to Component Connector End View Index.

Component View: Reference

Refer to Disassembled Views.

Description and Operation

Refer to Transmission General Description.

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions.

Scan Tool: Reference

Refer to Control Module: References.

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Verify there are no DTCs set related to the following system/component:Q39A Torque Converter Clutch Pressure Control Solenoid Valve

- If other DTCs are set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no other DTCs are set

3. Verify the condition does not exist:Incorrect fluid level or condition - Transmission - Refer to Transmission Fluid Level and Condition Check

- If a condition exists

Repair or replace as necessary.

- Go to next step: If no condition exists

4. Clear the DTCs.

5. Perform the configuration/reset function: Refer to Learned Values Reset.

6. Road test the vehicle. - Refer to Road Test.

7. Verify DTC P0741, P0742 is not set.

- {Test failed 1 time (s) }If any of the DTCs are set

- Replace the component:K71 Transmission Control Module

- Refer to:Step 5

- {Test failed 2 time (s) }If any of the DTCs are set

- Replace the component: Control Valve Body

- Refer to:Step 5

- {Test failed 3 time (s) }If any of the DTCs are set

- Replace the component: T12 Automatic Transmission Assembly

- Refer to:Step 5

- Go to next step: If none of the DTCs are set

8. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to:Step 1

- Go to next step: If the DTC is not set

9. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Torque Converter Replacement

- Refer to Transmission Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0748, P0962, or P0963

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0748

Pressure Control Solenoid Valve 1 Control Circuit

DTC P0962

Pressure Control Solenoid Valve 1 Control Circuit Low Voltage

DTC P0963

Pressure Control Solenoid Valve 1 Control Circuit High Voltage

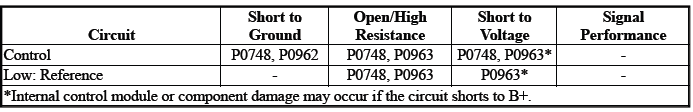

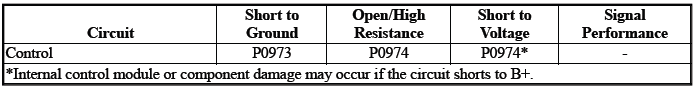

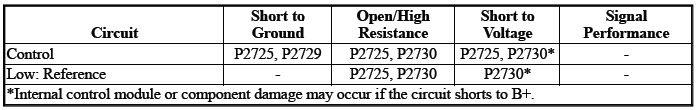

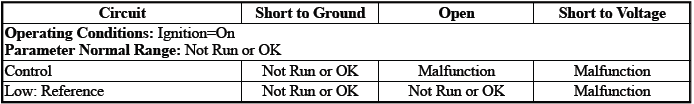

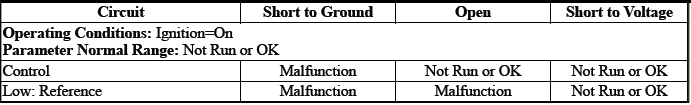

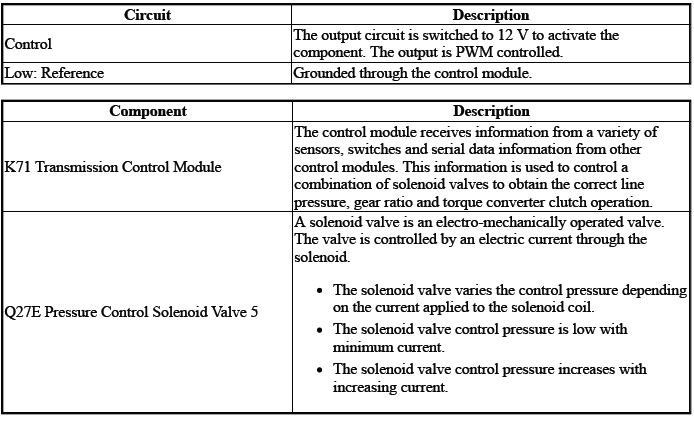

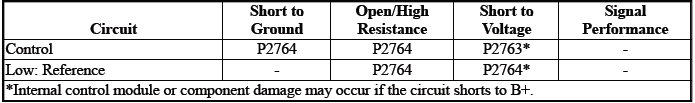

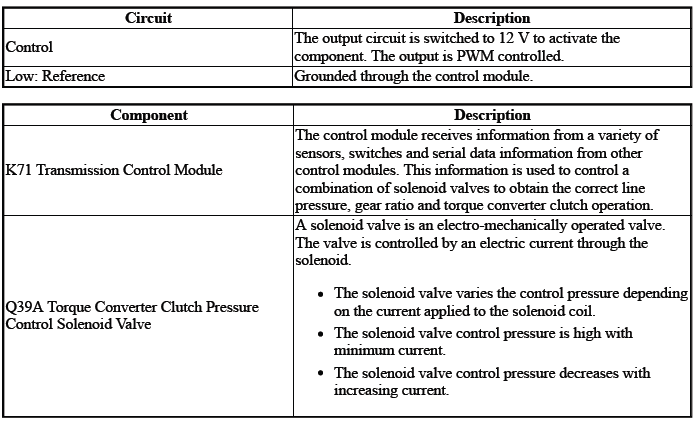

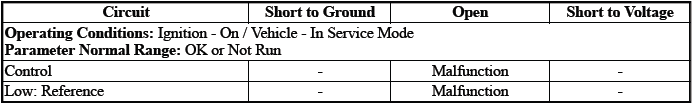

Diagnostic Fault Information

Typical Scan Tool Data

Pressure Control Solenoid Valve 1 Control Circuit High Voltage Test Status

Pressure Control Solenoid Valve 1 Control Circuit Low Voltage Test Status

Pressure Control Solenoid Valve 1 Control Circuit Open Test Status

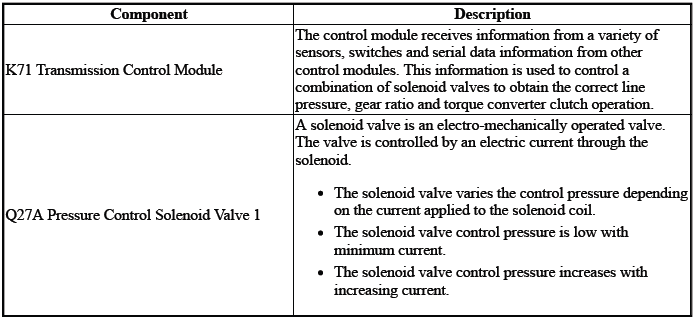

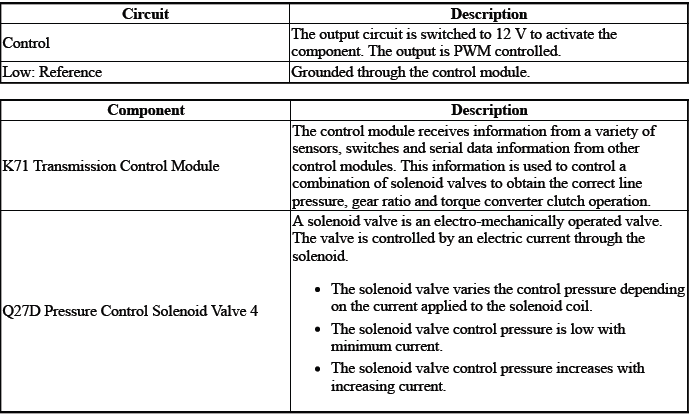

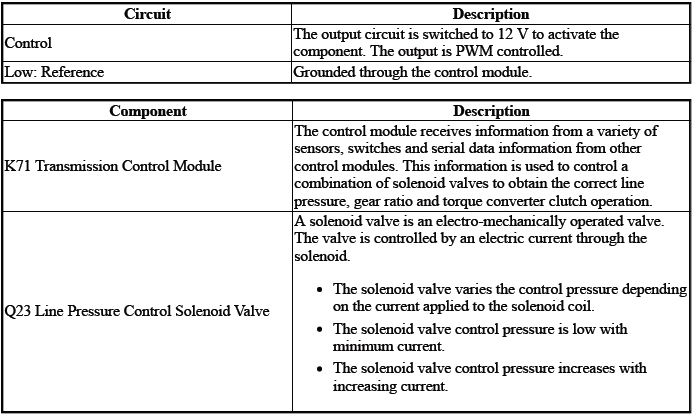

Circuit/System Description

The solenoid valve controls the flow of transmission fluid to the hydraulic actuator that controls the C1 clutch.

Conditions for Running the DTC

- { P0748 }DTC P0606, P0657, P0962, P0963, P0966, P0967, P0970, P0971, P2720, P2721, P2729, P2730, P2738, P2739 = Not set

- { P0962 }DTC P0606, P0657, P0963, P0967, P0971, P2721, P2730, P2739 = Not set

- { P0963 }DTC P0606, P0657, P0962, P0966, P0970, P2720, P2729, P2738, = Not set

- Ignition Voltage=9 to 32 V

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0748

Control Circuit=Commanded state does not match the actual state

P0962

Control Circuit=Less than 20 mA - For greater than 1 s

P0963

Control Circuit=Greater than 1358 mA - For greater than 1 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

- Fail-Safe Mode=Active

- Learning=Disabled

- Transmission gear allowed=3rd Gear - After a stop

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics.

Connector End View: Reference

Refer to Component Connector End View Index.

Component View: Reference

Refer to Disassembled Views.

Description and Operation

Refer to Transmission General Description.

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions.

Scan Tool: Reference

Refer to Control Module: References.

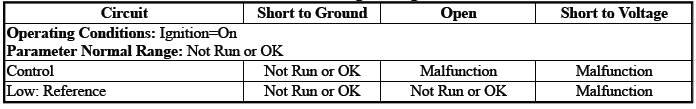

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Perform the scan tool control function:Pressure Control Solenoid Valve 1 - Increase & Decrease

Verify the scan tool parameter:

- Pressure Control Solenoid Valve 1 High Voltage Test Status=Not Run or OK

- Pressure Control Solenoid Valve 1 Control Circuit Low Voltage Test Status=Not Run or OK

- Pressure Control Solenoid Valve 1 Control Circuit Open Test Status=Not Run or OK

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

3. Perform the scan tool control function:Pressure Control Solenoid Valve 1 - Enable & Disable

Verify the component produces a clicking sound:Q27A Pressure Control Solenoid Valve 1

- If the component does not produce a sound

Refer to Circuit/System Testing

- Go to next step: If the component produces a sound

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

5. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

2. Remove the component:K71 Transmission Control Module

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control circuit terminal 13 & Low: Reference circuit terminal 14

- If not between 5.0 and 5.6 ohms

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27A Pressure Control Solenoid Valve 1

- Test for less than 2 ohms between the test points:

- Control circuit terminal 2@Component harness & Control circuit terminal 13@Control module harness

- Low: Reference circuit terminal 1@Component harness & Low: Reference circuit terminal 14@Control module harness

- If 2 ohms or greater - Replace the component:Automatic Transmission Wiring Harness

- If less than 2 ohms - Replace the component:Q27A Pressure Control Solenoid Valve 1

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:

- Control circuit terminal 13 & Transmission Case

- Low: Reference circuit terminal 14 & Transmission Case

- If less than infinite resistance

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27A Pressure Control Solenoid Valve 1

- Test for infinite resistance between the test points:

- Control circuit terminal 2@Component harness & Transmission Case

- Low: Reference circuit terminal 1@Component harness & Transmission Case

- If less than infinite resistance - Replace the component:Automatic Transmission Wiring Harness

- If infinite resistance - Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. Replace the component:K71 Transmission Control Module

Component Testing

1. Ignition/Vehicle - Off.

2. Disconnect the electrical connector:Q27A Pressure Control Solenoid Valve 1.

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control terminal 2 & Low: Reference terminal 1

- If not between 5.0 and 5.6 ohms

Replace the component:Control Valve Body

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:Each terminal of the component & The component's housing

- If less than infinite resistance

Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Wiring Harness Wire Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0776, P07A2, or P2719

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis:Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

DTC Descriptor

DTC P0776

Transmission Control Solenoid Valve 2 Stuck Off

DTC P07A2

Transmission Clutch 1 Performance

DTC P2719

Transmission Control Solenoid Valve 4 Performance

Circuit/System Description

When in Drive, the solenoid valve controls pressure to the C1 clutch regulator valve, or when in Reverse, the solenoid valve controls pressure to the C3 clutch regulator valve. These DTC's indicate a hydraulic /mechanical problem with the valve body or fluid pressure which is controlled by solenoid valves and is part of the control solenoid valve assembly which has no serviceable parts. With a loss of pressurized fluid, an incorrect gear ratio may result causing a Neutral condition or NO drive in all gears.

Conditions for Running the DTC

P0776, P07A2, P2719

- DTC P0563, P0601, P0602, P0604, P0711, P0712, P0713, P0717, P07BF, P07C0, P0722, P0741, P0742, P0748, P077C, P077D, P0798, P0962, P0963, P0970, P0971 = Not set

- Battery Voltage=9 to 32 V

- { P0776 }Current Gear=1, 2, 3, 4, 5

- { P07A2 }Current Gear=1, 2, 3, 4, 6

- { P2719 }Current Gear=Reverse & Shift Solenoid Valve 1 Command=Off

- Engine Speed=Greater than 600 RPM

- Garage Shift =No

- Ignition=On

- Transmission Fluid Temperature=Warmer than -10ºC (14ºF)

- Transmission ISS=Less than 200 RPM

- Transmission OSS=Less than 501 RPM

- Transmission Torque Command=Off

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

Condition 1

- Transmission Fluid Temperature=Warmer than 0ºC (32ºF)

- The difference between the following parameters is less than 150 RPM:Engine Speed & Transmission Input Speed - For greater than 3 s

Condition 2

- Transmission Fluid Temperature=-10 to -1ºC (14 to 30ºF)

- The difference between the following parameters is less than 300 RPM:Engine Speed & Transmission Input Speed - For greater than 10 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type C DTC - Exceptions listed below - Additional actions taken:

- Engagement of Reverse Gear=Shift Solenoid Valve 1 Command - ON

- Learning=Disabled

DTC P0776=DTC A - Additional actions taken:

- Torque Converter Clutch Solenoid Control=Disabled

- Manual Shift Control=Disabled

Conditions for Clearing the DTC

- DTCs listed in the DTC Descriptor Category=Type C DTC

- DTC P0776=DTC A

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics.

Connector End View: Reference

- Refer to Component Connector End View Index

- Refer to Inline Harness Connector End View Index

Component View: Reference

Refer to Disassembled Views.

Description and Operation

- Refer to Electronic Component Description

- Refer to Transmission General Description

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions.

Scan Tool: Reference

Refer to Control Module: References.

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode.

2. Verify there are no DTCs set related to the following system/component:

- Q27A Pressure Control Solenoid Valve 1

- Q27B Pressure Control Solenoid Valve 2

- Q27D Pressure Control Solenoid Valve 4

- If other DTCs are set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no other DTCs are set

3. Verify the condition does not exist:Incorrect fluid level or condition - Transmission - Refer to Transmission Fluid Level and Condition Check.

- If a condition exists

Repair or replace as necessary.

- Go to next step: If no condition exists

4. Verify there are no DTCs set related to the following system/component:K173 Transmission Range Control Module - If equipped

- If any DTC is set

Refer to: Diagnostic Trouble Code (DTC) List - Vehicle

- Go to next step: If no DTC is set

5. Clear the DTCs.

6. Perform the configuration/reset function: Refer to Learned Values Reset.

7. Road test the vehicle. - Refer to Road Test.

8. Verify DTC P0776, P07A2, P2719 is not set.

- {Test failed 1 time (s) }If any of the DTCs are set

- Replace the component: Control Valve Body

- Refer to:Step 5

- {Test failed 2 time (s) }If any of the DTCs are set

- Replace the component: K71 Transmission Control Module

- Refer to:Step 5

- {Test failed 3 time (s) }If any of the DTCs are set

- Replace the component: T12 Automatic Transmission Assembly

- Refer to:Step 5

- Go to next step: If none of the DTCs are set

9. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to:Step 1

- Go to next step: If the DTC is not set

10. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Transmission Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0778, P0966, or P0967

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

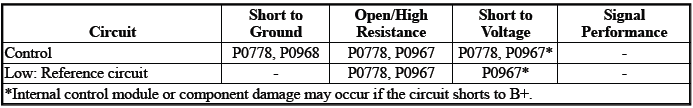

DTC Descriptor

DTC P0778

Pressure Control Solenoid Valve 2 Control Circuit

DTC P0966

Pressure Control Solenoid Valve 2 Control Circuit Low Voltage

DTC P0967

Pressure Control Solenoid Valve 2 Control Circuit High Voltage

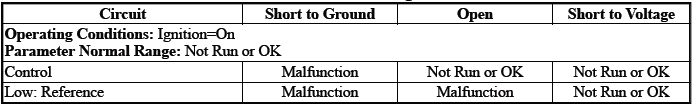

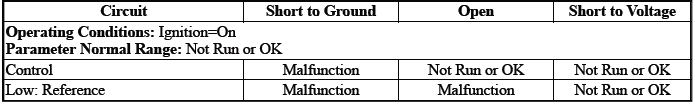

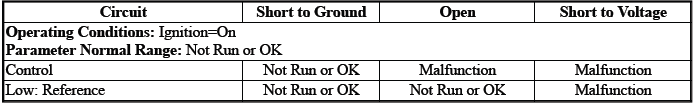

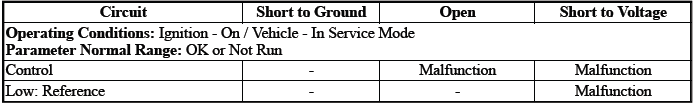

Diagnostic Fault Information

Typical Scan Tool Data

Pressure Control Solenoid Valve 2 Control Circuit High Voltage Test Status

Pressure Control Solenoid Valve 2 Control Circuit Low Voltage Test Status

Pressure Control Solenoid Valve 2 Control Circuit Open Test Status

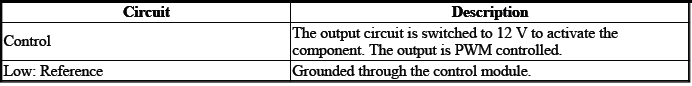

Circuit/System Description

The solenoid valve controls the flow of transmission fluid to the hydraulic actuator that controls the C2 clutch.

Conditions for Running the DTC

- { P0778 }DTC P0606, P0657, P0962, P0963, P0966, P0967, P0970, P0971, P2720, P2721, P2729, P2730, P2738, P2739 = Not set

- { P0966 }DTC P0606, P0657, P0963, P0967, P0971, P2721, P2730, P2739 = Not set

- { P0967 }DTC P0606, P0657, P0962, P0966, P0970, P2720, P2729, P2738, = Not set

- Ignition Voltage=9 to 32 V

Frequency the DTC runs=Continuously - After the running conditions are met

Conditions for Setting the DTC

P0778

Control Circuit=Commanded state does not match the actual state

P0966

Control Circuit=Less than 20 mA - For greater than 1 s

P0967

Control Circuit=Greater than 1358 mA - For greater than 1 s

Actions Taken When the DTC Sets

DTCs listed in the DTC Descriptor Category=Type A DTC

- Fail-Safe Mode=Active

- Learning=Disabled

- Transmission gear allowed=3rd Gear - After a stop

Conditions for Clearing the DTC

DTCs listed in the DTC Descriptor Category=Type A DTC

Reference Information

Schematic: Reference

Refer to Automatic Transmission Controls Wiring Schematics.

Connector End View: Reference

Refer to Component Connector End View Index.

Component View: Reference

Refer to Disassembled Views.

Description and Operation

Refer to Transmission General Description.

Electrical Information: Reference

- Refer to Circuit Testing

- Refer to Connector Repairs

- Refer to Testing for Intermittent Conditions and Poor Connections

- Refer to Wiring Repairs

DTC Type: Reference

Refer to Powertrain Diagnostic Trouble Code (DTC) Type Definitions.

Scan Tool: Reference

Refer to Control Module: References.

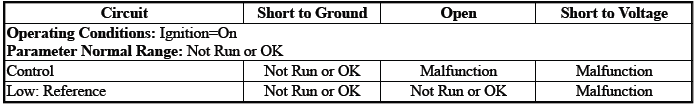

Circuit/System Verification

1. Ignition - On / Vehicle - In Service Mode

2. Perform the scan tool control function:Pressure Control Solenoid Valve 2 - Enable & Disable

Verify the scan tool parameter:

- Pressure Control Solenoid Valve 2 Control Circuit High Voltage Test Status=Not Run or OK

- Pressure Control Solenoid Valve 2 Control Circuit Low Voltage Test Status=Not Run or OK

- Pressure Control Solenoid Valve 2 Open Circuit Test Status=Not Run or OK

- If not the specified state

Refer to Circuit/System Testing

- Go to next step: If the specified state

3. Perform the scan tool control function:Pressure Control Solenoid Valve 2 - Increase & Decrease

Verify the component produces a clicking sound:Q27B Pressure Control Solenoid Valve 2

- If the component does not produce a sound

Refer to Circuit/System Testing

- Go to next step: If the component produces a sound

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing

- Go to next step: If the DTC is not set

5. All OK.

Circuit/System Testing

NOTE: It may take up to 2 min for all vehicle systems to power down before an accurate ground or low reference circuit continuity test can be performed.

1. Ignition/Vehicle & All vehicle systems - Off

NOTE: Twisting or tilting of the transmission control module electrical connector while disconnecting may result in bent or misaligned electrical terminal pins.

2. Remove the component:K71 Transmission Control Module

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control circuit terminal 8 & Low: Reference circuit terminal 9

- If not between 5.0 and 5.6 ohms

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27B Pressure Control Solenoid Valve 2

- Test for less than 2 ohms between the test points:

- Control circuit terminal 2@Component harness & Control circuit terminal 8@Control module harness

- Low: Reference circuit terminal 1@Component harness & Low: Reference circuit terminal 9@Control module harness

- If 2 ohms or greater - Replace the component:Automatic Transmission Wiring Harness

- If less than 2 ohms - Replace the component:Q27B Pressure Control Solenoid Valve 2

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:

- Control circuit terminal 8 & Transmission Case

- Low: Reference circuit terminal 9 & Transmission Case

- If less than infinite resistance

- Remove the component:Control Valve Body Cover

- Disconnect the electrical connector:Q27B Pressure Control Solenoid Valve 2

- Test for infinite resistance between the test points:

- Control circuit terminal 2@Component harness & Transmission Case

- Low: Reference circuit terminal 1@Component harness & Transmission Case

- If less than infinite resistance - Replace the component:Automatic Transmission Wiring Harness

- If infinite resistance - Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. Replace the component:K71 Transmission Control Module

Component Testing

1. Ignition/Vehicle - Off

2. Disconnect the electrical connector:Q27B Pressure Control Solenoid Valve 2

NOTE: The component's temperature should be 19 to 21ºC (66 to 70ºF) while testing.

3. Test for 5.0 to 5.6 ohms between the test points:Control terminal 2 & Low: Reference terminal 1

- If not between 5.0 and 5.6 ohms

Replace the component:Control Valve Body

- Go to next step: If between 5.0 and 5.6 ohms

4. Test for infinite resistance between the test points:Each terminal of the component & The component's housing

- If less than infinite resistance

Replace the component:Control Valve Body

- Go to next step: If infinite resistance

5. All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair: Refer to Diagnostic Repair Verification

- Refer to Control Valve Body Replacement

- Refer to Wiring Harness Wire Replacement

- For control module replacement, programming, and setup: Refer to Control Module: References

DTC P0798, P0970, or P0971

Diagnostic Instructions

- Perform the Diagnostic System Check prior to using this diagnostic procedure: Refer to Diagnostic System Check - Vehicle

- Review the description of Strategy Based Diagnosis: Refer to Strategy Based Diagnosis

- An overview of each diagnostic category can be found here: Refer to Diagnostic Procedure Instructions

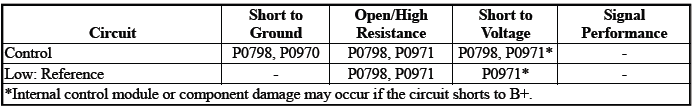

DTC Descriptor

DTC P0798

Pressure Control Solenoid Valve 3 Control Circuit

DTC P0970

Pressure Control Solenoid Valve 3 Control Circuit Low Voltage

DTC P0971

Pressure Control Solenoid Valve 3 Control Circuit High Voltage

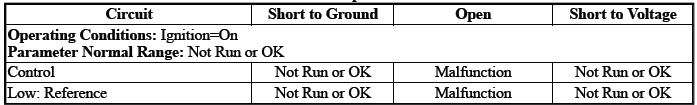

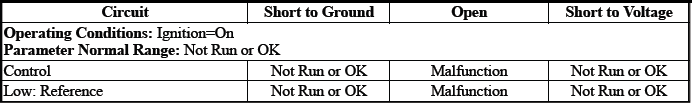

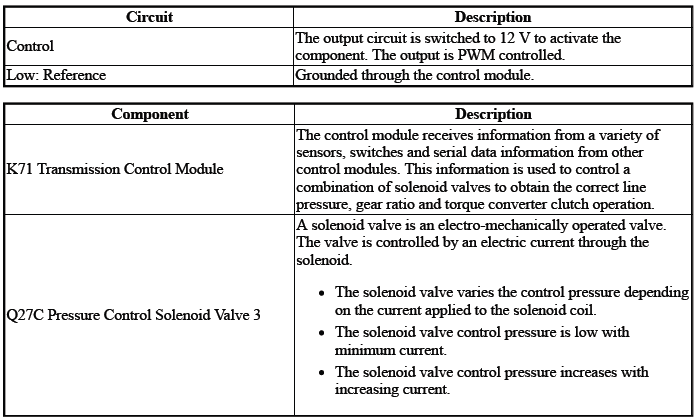

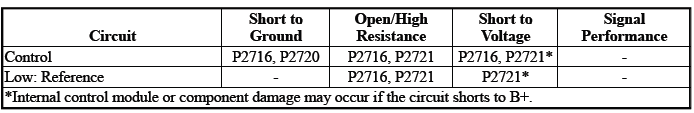

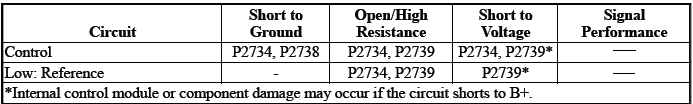

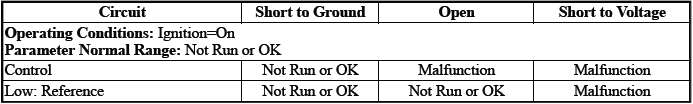

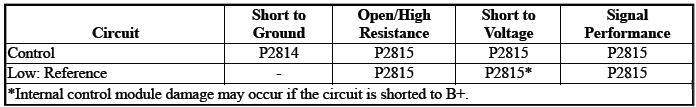

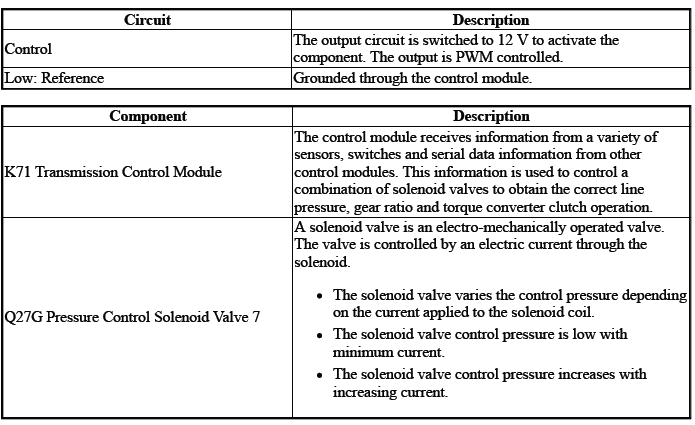

Diagnostic Fault Information

Typical Scan Tool Data

Pressure Control Solenoid Valve 3 Control Circuit High Voltage Test Status

Pressure Control Solenoid Valve 3 Control Circuit Low Voltage Test Status

Pressure Control Solenoid Valve 3 Control Circuit Open Test Status

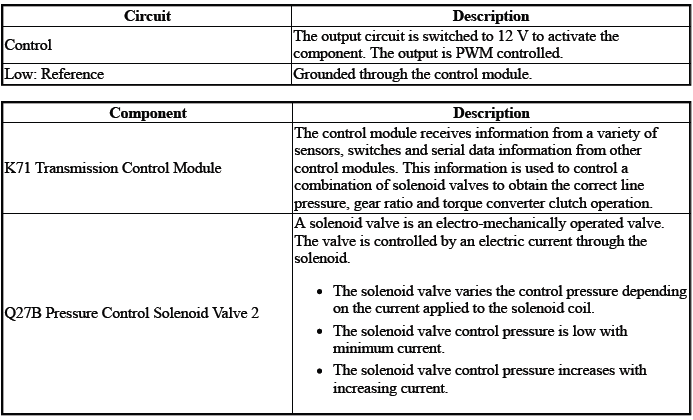

Circuit/System Description

For an overview of the component/system, refer to Transmission General Description

The solenoid valve controls the flow of transmission fluid to the hydraulic actuator that controls the C3 clutch.

Conditions for Running the DTC

- { P0798 }DTC P0606, P0657, P0962, P0963, P0966, P0967, P0970, P0971, P2720, P2721, P2729, P2730, P2738, P2739 = Not set

- { P0970 }DTC P0606, P0657, P0963, P0967, P0971, P2721, P2730, P2739 = Not set

- { P0971 }DTC P0606, P0657, P0962, P0966, P0970, P2720, P2729, P2738, = Not set

- Ignition Voltage=9 to 32 V

Frequency the DTC runs=Continuously - After the running conditions are met - For greater than 2 s

Conditions for Setting the DTC

P0798

Control Circuit=Commanded state does not match the actual state - For greater than 1 s

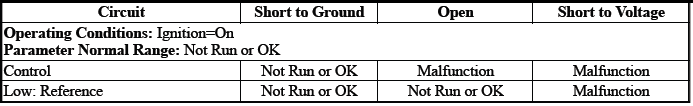

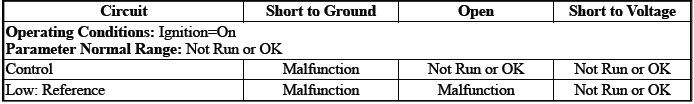

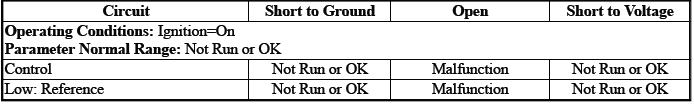

P0970